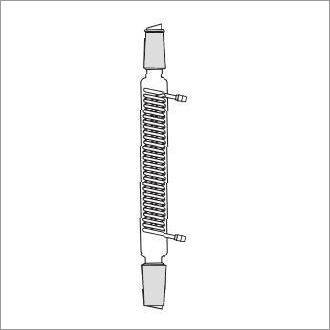

Coil Condensers (Reversible)

80.00 - 500.00 INR/Piece

Product Details:

X

Coil Condensers (Reversible) Price And Quantity

- 10 Piece

- 80.00 - 500.00 INR/Piece

Coil Condensers (Reversible) Trade Information

- Cash in Advance (CID) Cash Advance (CA)

- 500 Piece Per Day

- 1 Week

- Carton Box

- Australia South America Eastern Europe Western Europe Middle East Africa Central America Asia North America

- All India

Product Description

Coil condensers are heat exchange devices used in various industries and laboratories for efficient cooling and condensation of vapors or gases. They consist of a coiled tube that facilitates the transfer of heat from the vapor or gas to a cooling medium, resulting in condensation.

Frequently Asked Questions :

Q: What is the purpose of a coil condenser?

A: The main purpose of a coil condenser is to facilitate the condensation of vapors or gases into a liquid state. By circulating a cooling medium, such as water or air, around the coiled tube, heat is transferred from the vapor or gas, causing it to cool and condense.

Q: Where are coil condensers used?

A: Coil condensers are used in various industries and applications. They are commonly found in distillation setups, reflux systems, solvent recovery processes, and chemical laboratories. They play a vital role in cooling and condensing vapors for the separation and purification of substances.

Q: How does a coil condenser work?

A: A coil condenser operates based on the principle of heat exchange. The vapor or gas flows through the coiled tube, and a cooling medium circulates around it. As the vapor or gas comes into contact with the cooler surface of the tube, heat is transferred, causing it to cool down and condense into a liquid state.

Q: What are the advantages of using coil condensers?

A: Coil condensers offer several advantages. They provide efficient heat transfer, allowing for effective condensation of vapors or gases. They are compact in design, which makes them suitable for applications where space is limited. Additionally, they are relatively easy to assemble, maintain, and clean.

Q: Can coil condensers be customized for specific applications?

A: Yes, coil condensers can be customized to meet specific application requirements. The length, diameter, and material of the coiled tube can be tailored to suit the desired cooling capacity and compatibility with the substances being condensed. Customization ensures optimal performance and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

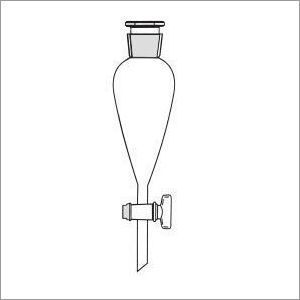

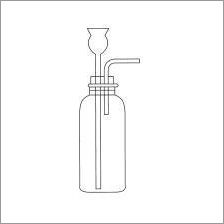

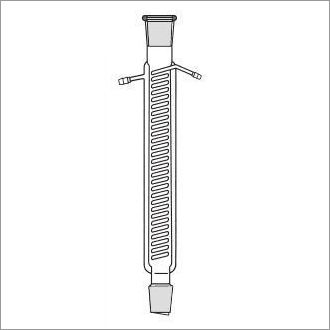

Other Products in 'Glassware Instruments' category

SADANA BROTHERS

SCI-LAB SOLUTION

SCI-LAB SOLUTION

Send Inquiry

Send Inquiry Send SMS

Send SMS